An intelligent mold temperature control supports the quality and dimensional accuracy of the casting as well as the economy of the casting process. Intelligent temperature control means planning the heat balance of tools and designing and constructing all measures in a specific and targeted way. In order to achieve an optimal result for all relevant quantities such as casting quality, process stability, cycle time or tool life, the process heat must be dissipated from specific areas of the tool in a targeted and timed manner.

In the thermally relevant tool segments, the temperature control must be individual, efficiently controllable and possibly variable in time. The corresponding tool segments must therefore be thermally quick. This is possible thanks to the near-contour and contour-adjusted tempering channels, different heat-conducting materials in the die casting tool and powerful heating / cooling devices with the option of vario-thermal control.

How can this be done during tool design? For 30 years, possibilities of computer-aided, optimized design of casting processes and modern, partly generative manufacturing technologies for contoured and contour-adjusted mold segments have been available. The potential of virtual casting process assessments and optimization are recognized and quantifiable - ready to be leveraged. With the “front loading” approach, which has been known in mechanical engineering for 140 years, the virtually generated knowledge about the individual casting process can already be used in the construction and design of the casting tool.

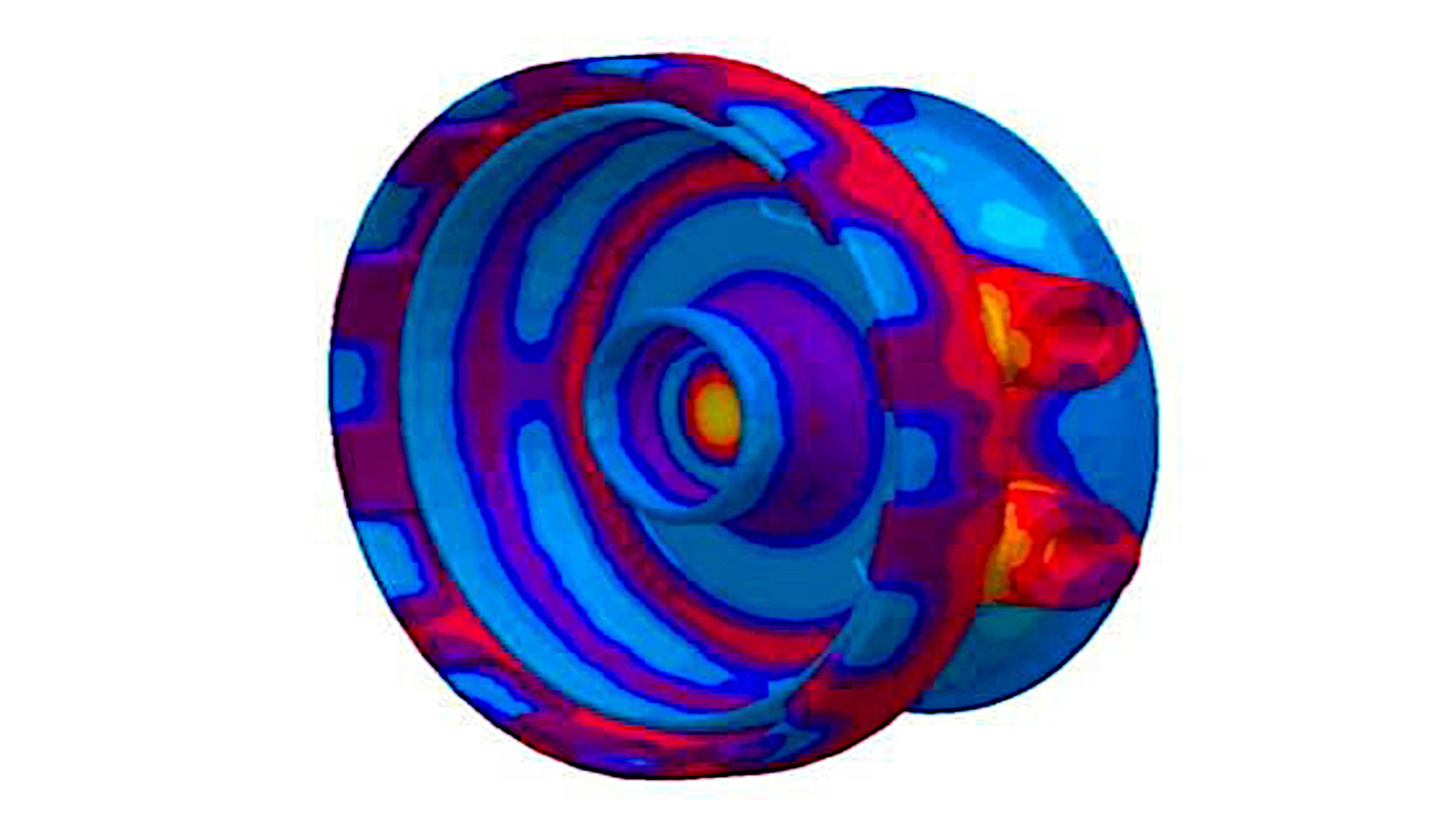

The porosity can be eliminated by appropriate temperature control of the tool at the critical points. There are hundreds of options for dimensioning the temperature control: different switch-on and switch-off times, different flow temperatures and flow rates of the temperature control medium led e.g. in this example, to over 700 conceivable variants, of which a statistically relevant part was examined in a virtual DOE. This virtual DOE consists of casting process simulations of 50 variants, which represent the range of all meaningful parameters of temperature control.

The results of these calculations now allow the evaluation of the different variants with regard to different criteria such as cycle time, volume of porosity or service life of the tools in critical areas.