13

- Hall 4 / Booth Number 4-330

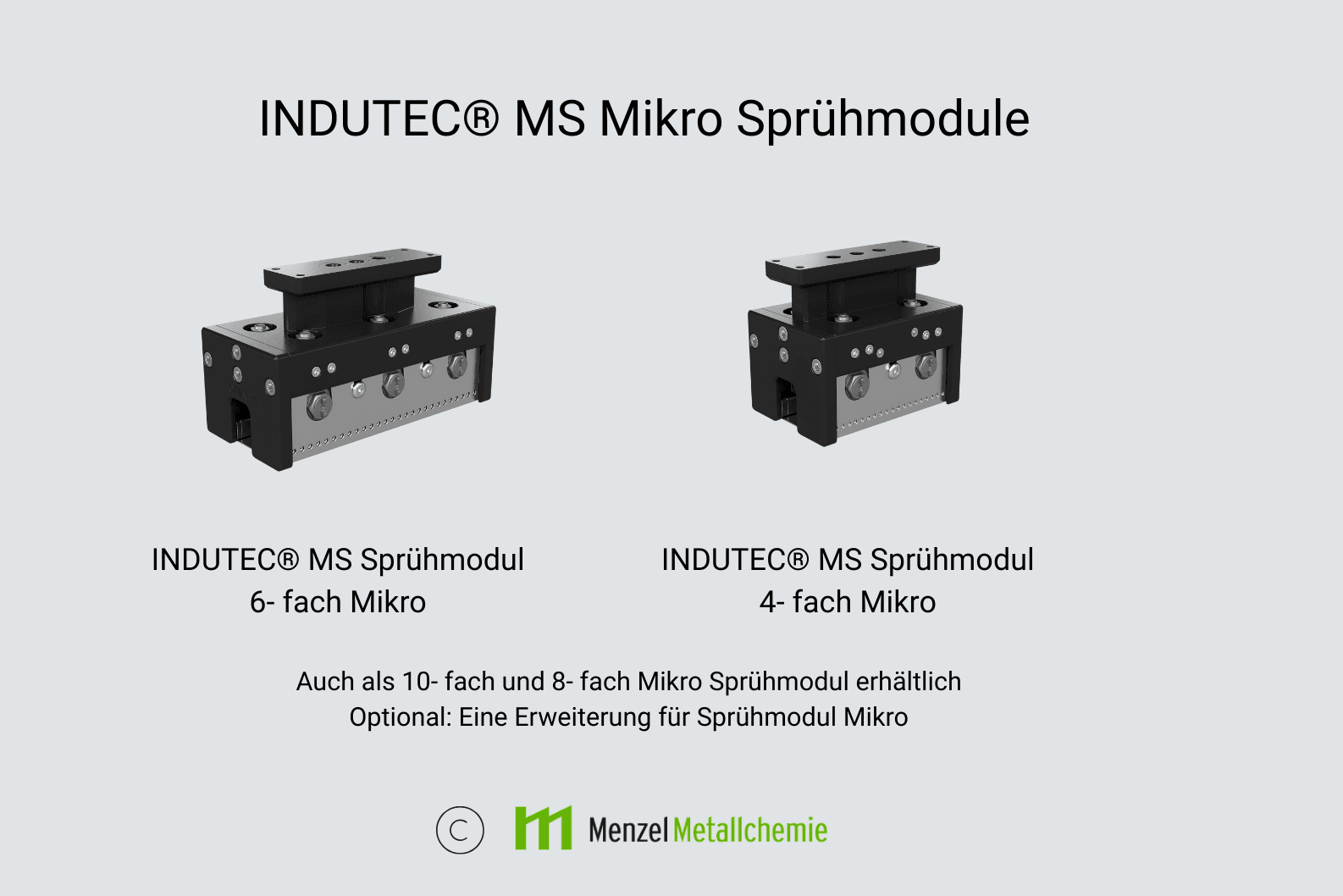

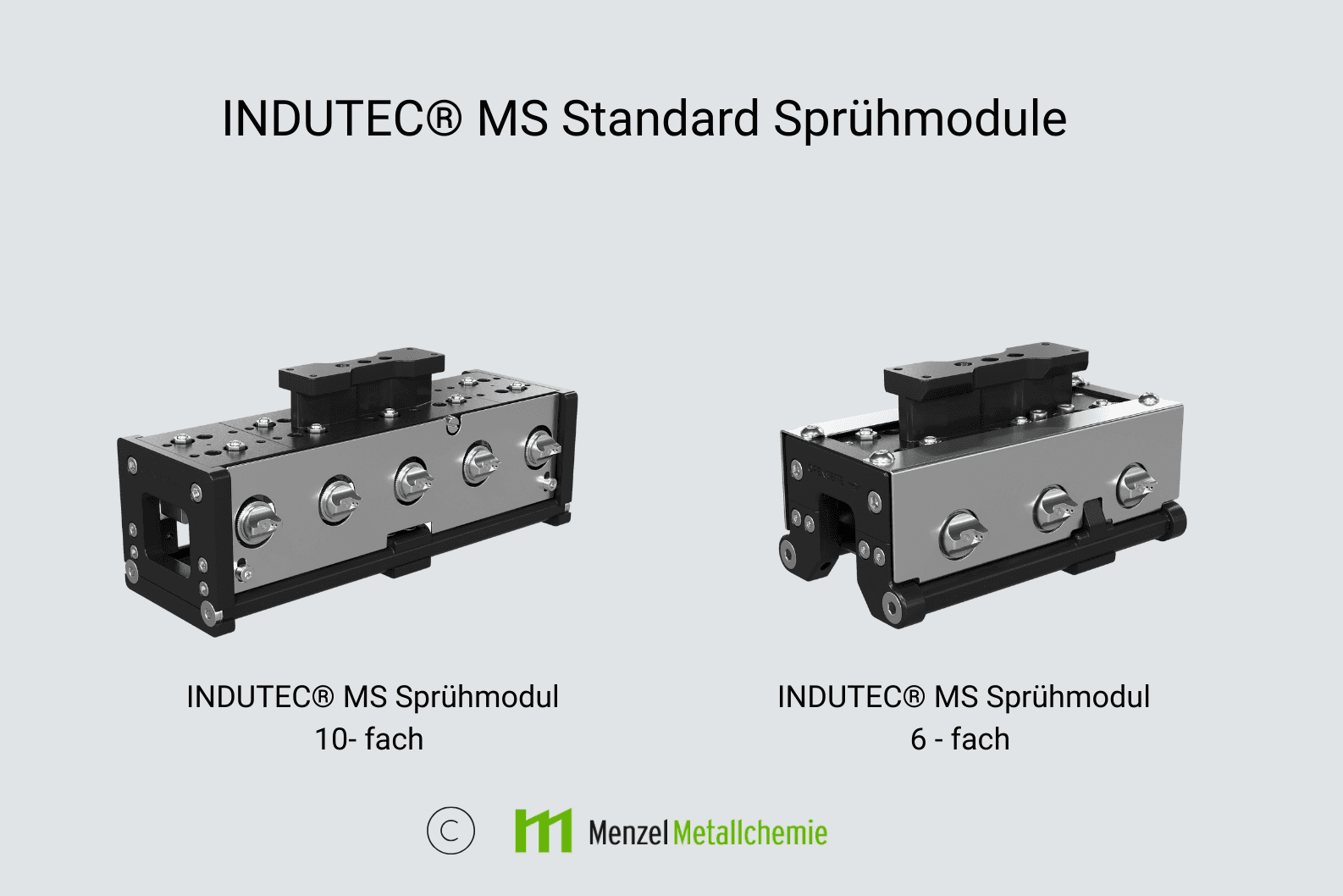

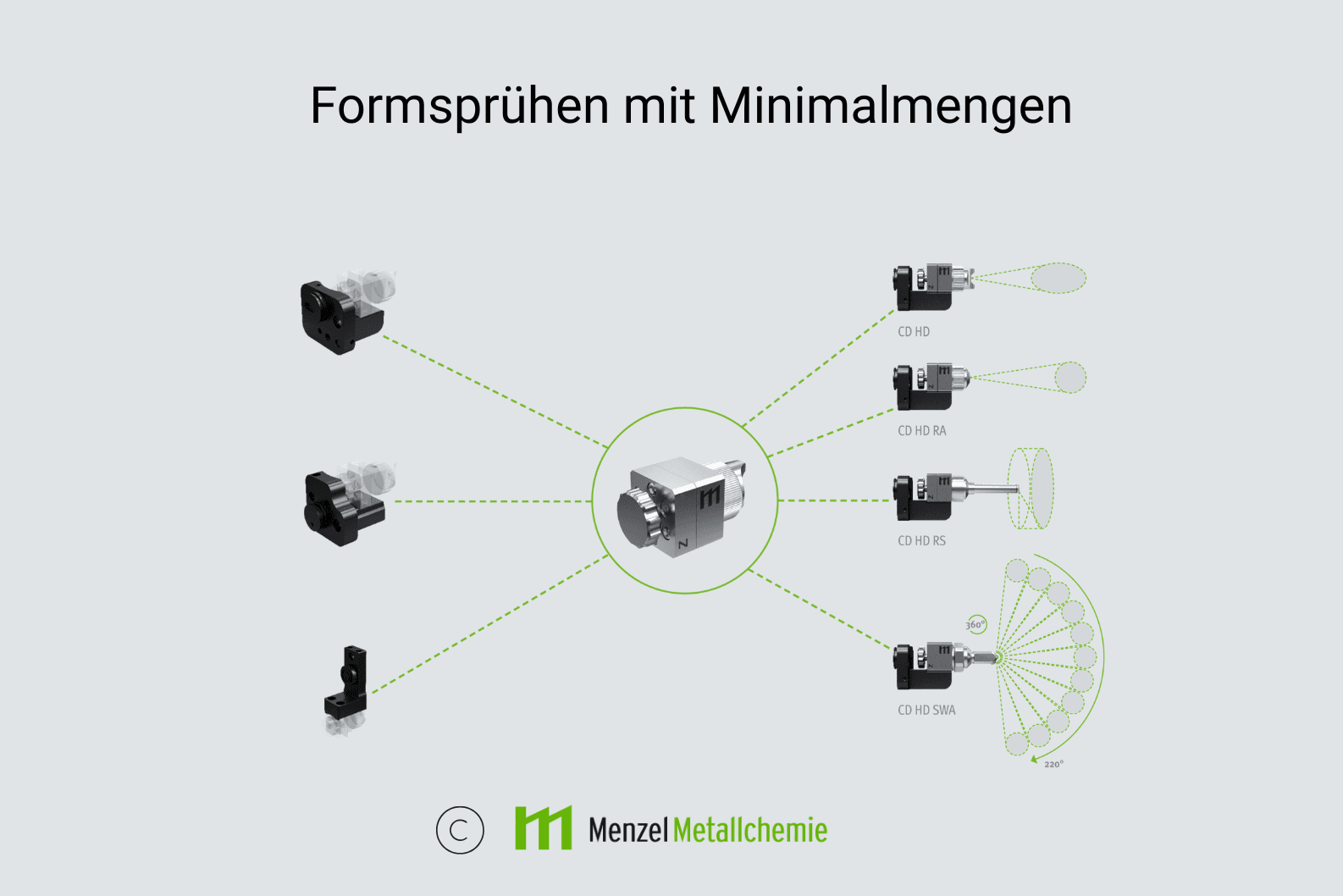

Micro-spraying on die-casting machines (Cold- /Hot- chamber)

Key Facts

- Cost reduction through material savings up to 70%

- No sticking after machine shutdown due to the self-cleaning effect of the spray nozzles

- Reduction of cycle times, as blowing out is eliminated in most cases or does not need to be done twice

Categories

Release agent spraying systems and equipment

Product information

Precise. Reliable. Consistently accurate.

Minimal effort, maximum effect!

Conventional spraying onto the mold or into the cavities often leads to a quenching effect, which negatively impacts the mold's lifespan.

In addition, inaccurate spraying processes consume large amounts of release agent, which in turn leads to emissions in the production hall and increases both cleaning and disposal costs.

On the other hand, micro-spraying/minimal quantity lubrication (MQL) with release agent results in good surface quality with consistent results.

The advantage is that the nozzles do not need adjustment, clog, or dry out. They do not dry up even when the machine is idle on weekends. T ...